Your online sheet metal cutting and bending service

Most people don’t understand how beneficial sheet metal fabrication services actually are. Sheet metal fabrication is a form of technology that is used for thin metal parts. It goes great with prototypes and finished products. This form of technology has dramatically changed the way most industries function. Sheet metal fabrication has three steps; cutting, forming and finishing. These three steps are used to create almost anything made of metal. This process is unique because the selection process can be done online. This makes it a lot easier to pick and select everything needed for sheet metal fabrication.

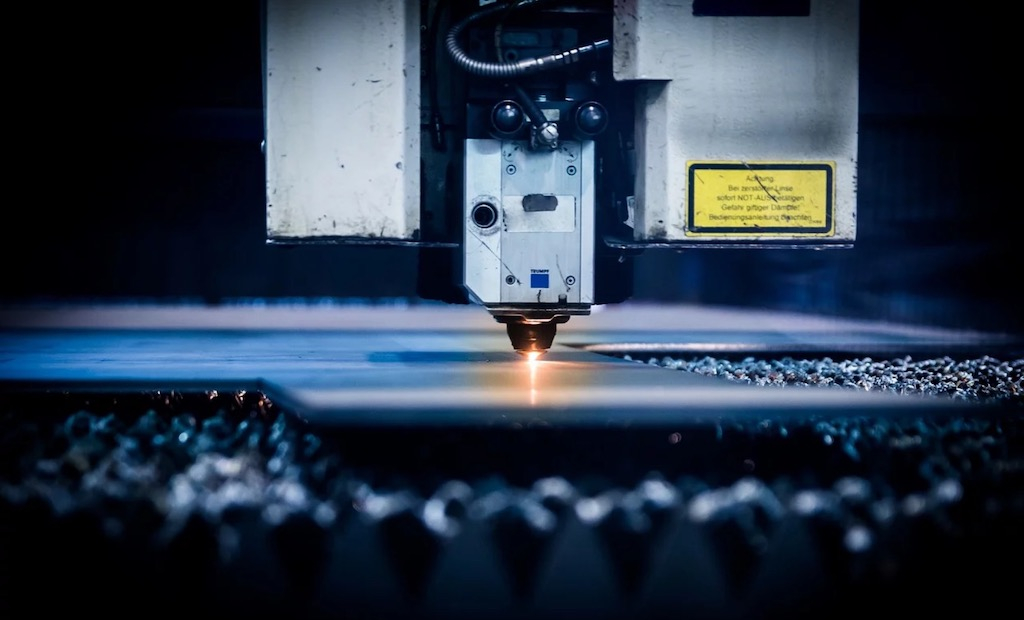

Cutting/Bending

There are multiple ways to cut sheet metal into smaller pieces, but please be aware of the available metal that is offered. They can choose from Aluminum 6061-T6, Aluminum 5754, Aluminum 5052, Mild Steel 1018, Stainless Steel 304, Stainless Steel 316L, and Copper C110. Once the type of metal is selected, the laser cutting or bending process will begin. The laser cutting can be between 0.5 – 10 mm thick, and the bending process ranges between 0.5 – 6 mm thick. Once they have selected their desired cutting and material, the electrical discharge machine (EDM) is put to use. This machine does all of the hard work by getting the material ready for the next step.

Forming

The forming process begins as soon as the cutting process is finished. This is where the metal will be formed into its desired shape. Sheet metal is used for many different things, such as car parts, soda cans, or almost anything that consists of metal. There are many different techniques for forming that can be performed. Those techniques consist of rolling, bending and forming, stamping, punching, and welding. Each technique is used for making different shapes and sizes for each object. This is the most important step because the forming turns the metal into the specific item the factory wants.

Finishing

The last step of this process is the finishing of the metal after everything has been formed. During this process, the metal will be polished and/or sharpened to remove any of the rough edges left over from the cutting and forming. They will also clean and rinse the metal to reassure that the metal is clean before it is delivered to its desired factory. After the cutting and forming process, the item may not be a store ready. This step is also important because it makes the items available for use by making it store ready.

As you can see, sheet metal fabrication is an important process when it comes to making our everyday metal products. This three-step process is very simple but takes a lot of detail. The selection process is made available online. This gives the user the ability to customise the materials and the type of cutting they want. Each of these three steps complements each other. The cutting of the material allows the forming process to be completed, and the finishing process allows the product to be sent to the factory.

The editorial unit

Facebook

Twitter

Instagram

YouTube

RSS