Rapid prototyping services: Low-volume productions

Using 3D hubs for rapid prototyping service

Manufacturing a new product often requires rapid prototyping to ensure your product meets design specifications and quality measures. Historically, prototyping was a demanding undertaking and took a considerable amount of time to complete to produce the first run of a product. Accordingly, the price can also be considered for product volumes when ordered at their minimum volume. The entire process used to be challenging, time-consuming, and expensive. Not anymore.

Breakthroughs on-demand

In the past, on-demand manufacturing didn’t exist, and the sourcing of parts at local machine shops was simply a part of how product solutions were developed. Those days are gone now that options such as stereolithography (SLA) 3D-printing for rapid prototyping services are available. You can tap into a global network of certified SLA rapid prototyping service and 3D-printing companies, thereby printing your high-detail prototype fast, at low-volume, and without sacrificing quality.

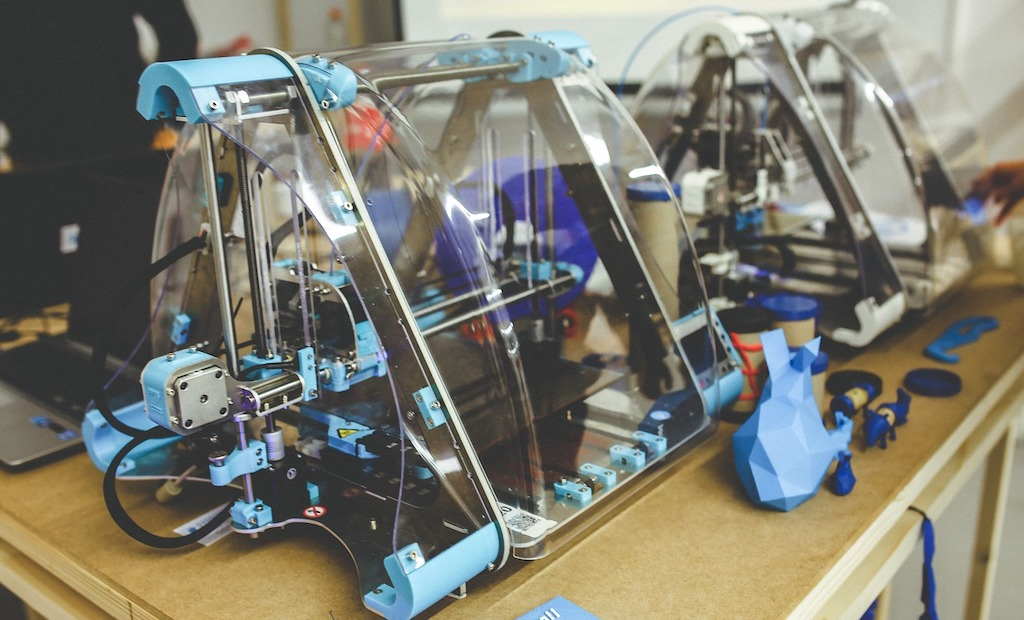

SLA 3D printing

SLA 3D printing technology makes it possible to create prototypes, models, patterns, and parts layer-by-layer using photo chemicals where light drives chemical monomers and oligomers to cross-link and form polymers. Using this technology and depth-of-experience, it’s now feasible to place parts into prototype production in less than five minutes from the acceptance of a quote.

Low-volume production

Previously, ordering large volumes of product at the prototyping stage was common due to processes, parts, and production expenses. However, low-volume production orders are now eminently feasible using 3D-printing hubs. You can now:

- Build and edit a prototype quote remotely

- Review parts for manufacturability

- Measure the production cost of individual raw materials

- Take advantage of rapid CNC turning service

These capabilities are some of the technologies and service growth in the industry that makes it possible to prototype at high-quality in record time. Achieving low-volume production on-demand, and also reporting the expected milestones for your project in real-time is becoming commonplace.

Technologies such as robotics, automation, and 3D-printing are more streamlined and available to drive prototyping and manufacturing. The technology itself is no longer the challenge, rather it’s the ability to do so at speed and scale, managing the complexity and quality of the prototyping and production that is the real test.

Consumers demand quick turnaround and real-time products. These technologies and management techniques allow companies to compress lifecycle development and compete with excellence in the changing, consumer-driven marketplace.

The editorial unit

Facebook

Twitter

Instagram

YouTube

RSS