Ceramic 3D printing: Could it speed up the production of essential vaccines?

One of the hottest topics in the current pandemic is the talk of developing vaccines. With many of the biggest names and cleverest people around the world engaged in the hunt for a coronavirus vaccine, could the world of ceramic 3D printing play a part in helping to solve the problem?

Ceramic 3D printing and vaccines

According to a team at additive manufacturing company Lithoz and the research organisations SINTEF and IBET, the answer is yes. They are working together on a project to allow the production of highly complex vaccines in large quantities and crucially at a much lower cost than normal.

The project is funded by the EU and is named NESSIE. It is just one example of technologies such as 3D printing can improve our healthcare system and is particularly working on the issues of slow and expensive development and production of vaccines. The current pandemic has highlighted the need for a much quicker and more cost-effective way to create vaccines, especially when new viruses appear.

Efficient vaccine production

Currently, it can take months or even years to develop a targeted vaccine and then the cost of it can simply be too high for some countries to afford. The idea behind NESSIE is to use the latest in 3D-printing technology to help address these issues.

Many vaccines use the viruses themselves to deliver the necessary elements of immunity that people need. But the viruses themselves are not only expensive to produce but need careful handling and expensive, purification measures to stop them from spreading.

The aim of the project is to make the vaccines more efficient to produce by creating new ways to purify viruses such as the adenovirus that is used for delivering genes or vaccines antigens into humans.

Novel approach

The NESSIE project makes use of Lithoz’s ultra-high-resolution, ceramic-3D-printing technology to create something called novel chromatographic columns. These are the most advanced purification technology available and offers a first of its kind system that combines tailored shapes and a new level of control over the porous level of materials.

So far, the tech has been used to create supports for adenovirus purification. The aim is to continue to develop the systems with the aim of making it far quicker to manufacture crucial vaccines as well as gene therapies that can help save lives across the world.

Helping to combat the problems

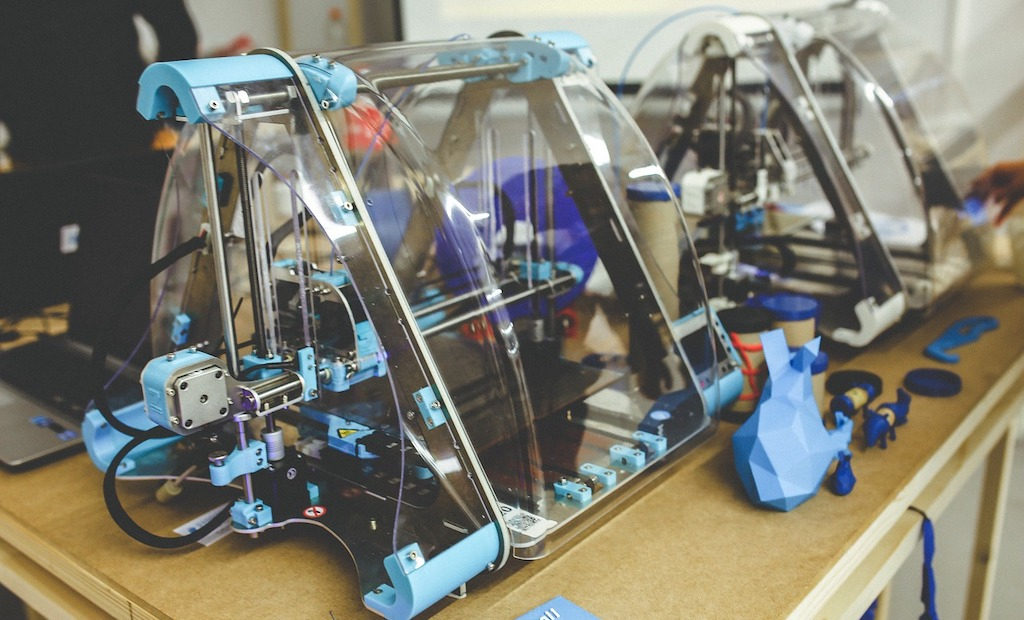

3D printing is already showing that it can offer new ways to combat the problems that have arisen during the Covid-19 pandemic and could help to deal with similar problems in the future.

The shortage of PPE is one example where the world of 3D printing offers a cost-effective and speedy resolution to a problem. With the ability to print parts for everything from masks to face shields, the 3D printing technology can help to ease shortages and even offer more cost-effective options than traditional routes.

Other examples include things like parts for medical equipment such as ventilators that can be quickly fabricated by 3D printing. While most companies don’t have the sterile settings needed to produce some types of medical equipment, others already have systems in place that are similar to those in medical equipment manufacturing companies.

Perhaps the biggest barrier so far is regulation and the speed at which these can be changed to allow 3D-printed parts into the supply chain. But the current pandemic has highlighted flaws in a number of systems and whether purifying viruses for vaccines or creating face masks, 3D printing has a strong part to play in the future.

The editorial unit

Facebook

Twitter

Instagram

YouTube

RSS