What are the advantages of subtractive manufacturing?

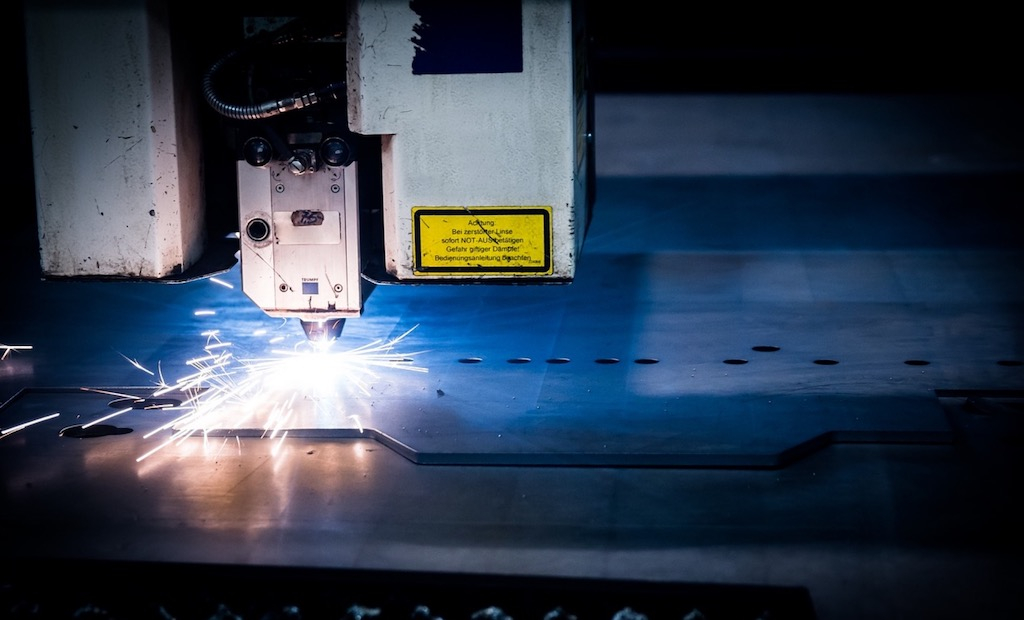

3D printing online is seen as a additive manufacturing process, which first started in the 1980s. Back then it was a novelty reserved for advanced laboratories. Slowly but surely it made waves in the medical sector as it is able to develop custom medical devices. In the early 2000s hobbyists and entrepreneurs saw the possibilities of 3D printing. During this time other manufacturing methods were also developed as. A great example of this is subtractive manufacturing, this can be used for CNC parts online. It offers a lot of advantages, such as these below.

Cheaper than 3D printing

Subtractive manufacturing processes are for example turning, milling and injection moulding. These remove material from a workpiece in order to create a three dimensional order. Additive manufacturing techniques on the other hand build a 3D part by adding layers of material, which is completely different. Although 3D printers are decreasing in terms of price, it is still more expensive than machining an item. This is partially the case due to the high costs of the materials used to 3D print. Another reason for 3D printing being more expensive is that the prints are not always qualitative, so you essentially waste high-cost materials.

No post-processing needed

CNC machined parts do not need post-processing in order to look attractive. This is not the case for the 3D printed products as their surfaces often need a subtractive manufacturing process to finish. Even if you do not want a finish, 3D printing is still less reliable than subtractive manufacturing techniques such as CNC milling and CNC turning, particularly with low-end machines which cannot produce items with consistent quality. To avoid this, you need a highly reliable printer, but these are very expensive. 3D printing can be useful however, especially for prototypes.

Familiar to designers

Another advantage of subtractive manufacturing is that it is often more familiar to designers than 3D printing. This is because a lot of designers use specific functions that are common in CNC lathes and mills. For these people, 3D printing does not have a clear benefit. These designers thus find it much better to CNC machine their concept into an actual product. 3D printing, or additive manufacturing, can be attractive in several applications, but not in this case. Instead it is better to use CNC milling, turning and moulding.

The editorial unit

Facebook

Twitter

Instagram

YouTube

RSS