Innovative examples of sustainable product design

Sustainable product design is the process of creating and manufacturing products and services whilst taking into consideration their environmental, economical and social impacts, from the initial stages right through to the product’s end of life. This article explores some incredible examples of innovative sustainable product design.

Adidas x Parley for the Ocean trainers

Adidas partnered up with environmental company Parley for the Oceans to create the first collection of running shoes made using recycled plastics and materials recovered from the ocean. The initiative saw just 50 pairs of shoes released, which were to be “earned” as opposed to purchased, meaning individuals looking to obtain a pair were required to undergo a competition on Instagram by posting a video demonstrating their commitment to avoiding using single-plastic products.

Originally designed by Alexander Taylor, the footwear is created using Adidas’s existing manufacturing processes for shoes, with the standard synthetic fibres swapped out for yarns made using the recycled Parley Ocean Plastic. The green wave pattern located on the uppers of the footwear has been created using recycled gill nets, sourced directly from the sea before being processed into eco-friendly fibres. The remainder of the upper is constructed by utilising plastic collected from waters surrounding the Maldives, where the government is collaborating with Parley to address the plastic waste issues. The original concept was unveiled as a prototype in July 2015, before a version combining the recycled uppers with 3D-printed soles, which used plastic from the ocean, was released later that year.

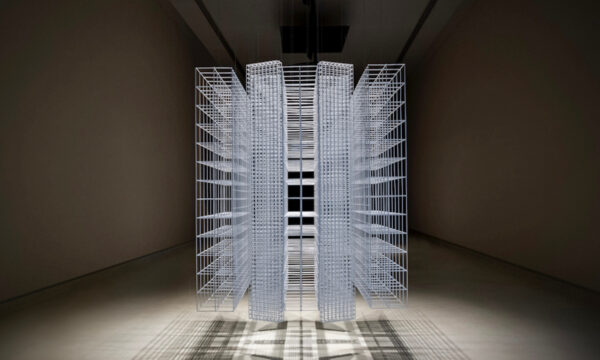

Sustainable kitchen units by Form Us with Love for Ikea

Kungsbacka is the first kitchen by Ikea that is created using recycled plastic bottles and recycled industrial wood. Each of the kitchen units contains 25 plastic bottles, designed by Swedish studio Form Us with Love, with the intention of making “sustainability available for everyone”.

The main structure of each kitchen is created using reclaimed wood, with the coating made using recycled plastic bottles. The studio decided on a simple outline in a matt grey colouring with the intent of producing a “timeless” design. The shiny black Hackås handles contrast against the matte surface of the cupboards. As is often found with most kitchen units from Ikea, each cabinet is modular and can be positioned to fit within almost any space.

Sustainable products are often far too expensive to produce, due to the extensive research and development that is typically involved. As a result, production strategies were required in order to ensure the kitchen units were viable alternatives to similar products on the market. The two companies expect the final product design of the units to be durable for 25 years, with Ikea working to introduce further sustainable product lines across their catalogue.

Solving issues with water contamination: The Peepoo bag

An excellent example of sustainable product design is the Peepoo bag, created by Swedish company Peepoople. The main aim of the bag is to solve issues with water contamination, predominantly within disaster-hit regions of the world.

The Peepoo consists of a small, biodegradable plastic bag with an inner lining made from urea. It is intended for single-use and is then tied at the top and disposed of. Urea is the core ingredient found within modern synthetic fertiliser, speeding up the breakdown of faeces or urine into ammonia and carbonate. The idea is that within two to four weeks the bag will decompose and sterilise the waste so that it’s no longer a health threat, and can even be used as fertiliser.

Edible six-pack rings to reduce ocean waste by Saltwater Brewery

Saltwater Brewery has utilised by-products left over from the brewing process in order to produce six-pack rings for beer cans that can be safely eaten by wildlife in the ocean.

The organisation collaborated with We Believers, a New York advertising agency, to substitute their plastic rings with bio-based materials made using edible wheat and barley.

By using waste materials from the beer-making process they have been able to develop what they perceive to be the first 100% biodegradable, edible and compostable packaging implemented in the beer and alcohol industry.

Initially, the group experimented using seaweed, however it became too rigid outside of the water, posing the potential risk of cutting or choking wildlife that came across it when washed up on the shore. It was then that they combined wheat and barley remaining after the brewing process and moulded this into the standard six-ring shape.

If the packaging ends up in the ocean, it can start breaking down within a few hours, further addressing the common issue of animals getting stuck in them. The organisation intends to produce 400,000 edible six-pack rings each month, at a cost of between 10 and 15 US cents per unit.

The editorial unit

Facebook

Twitter

Instagram

YouTube

RSS